More often than not, RFQ information arrives piecemeal, in three or four separate emails, often over a span of hours or even days. Estimators have to request additional information (material specs, 3D models, 2D detailed drawings, etc.). When the information arrives at different times, or on different days it adds frustration and confusion on both sides.

Here are the keys to a perfect RFQ.

Do your research

Before you hit send on the RFQ, have you done preliminary research to ensure the company you are requesting the quote for services from can actually deliver the product you are looking for? This research includes ensuring all the stakeholders in your company have been consulted to ensure the quote you prepare is as detailed as possible. If in doubt customer service is a phone call away to address any questions or concerns.

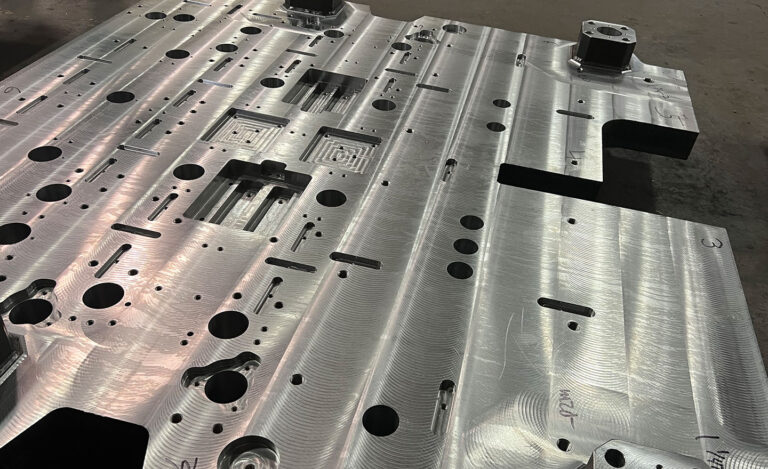

Take some time to vet potential suppliers to ensure that the OEM can deliver the product. For example, can the same OEM provide the fabrication and finishing? Will you need to arrange for transportation to an additional facility for finishing? Remember, each additional step in the chain can add cost, the risk of damage and problems with the finished product.

Send the quote by email

RFQs need to be in writing before a formal quote can be prepared, even if you already communicated the information in a telephone call. Ensure you:

- Include all necessary company information, including the corporate name, street address, phone number, website url, etc.

- Include all important contact information, such as the requestor’s first and last name (not just John or Tanya), title, phone numbers including extension number, email address and any additional or alternate contact names and information. It can also be helpful to include the time zone the contact person is located in.

- Make sure you are sending the quote to the correct email address at the manufacturer to prevent delays. Many companies have a dedicated email for quote requests, and while the quote will be redirected to the correct recipient, that can add a delay to response time.

Subject Line

Include pertinent information in the subject line, such as the job number,and details about the type of RFQ you are requesting, such as weldment, base, grinding etc.

Quote Details to include

What kind of product or service you are requesting?

- The quantity you are requesting

- 2D detail drawing w/ tolerances (.pdf format)

- 2D CAD file (.dxf format)

- 3D solid model (.stp format).

- Any special handling requests, including paint, finishes or other details such as finishing that do NOT need to be completed

- Delivery requirements if applicable

Advantages

The more complete and detailed the information you provide with the RFQ, the faster you can receive a detailed response and work can begin. Not only does following up for additional information result in delays, there is a risk that information will be missed or eaten by spam filters. Since precision and accuracy are essential in metal fabrications, details matter for both the cost and the finished product.

While not strictly necessary to the quote process, providing additional contacts can eliminate delays because the contact person is unavailable. Incomplete, unclear or missing information stops the quotation process in its tracks. It can also be beneficial to provide additional contacts in the engineering or XXX department in case clarification about the specifications is required. Information can be lost in transit, and being able to correspond directly with the people or department who can provide the additional information saves time for both manufacturer and customer.

While the bottom line is always an important consideration, it shouldn’t be the only one. An OEM that can provide end-to-end fabrication, including delivery, can save time, minimize the risk of error and deliver quality output to meet your specifications. Anchor Danly specializes in custom and catalog end-to-end metal fabrication.