Flatness and parallelism are two measurements that can have a significant impact on the final product, and while they sound similar, there are important differentiation’s.

Flatness

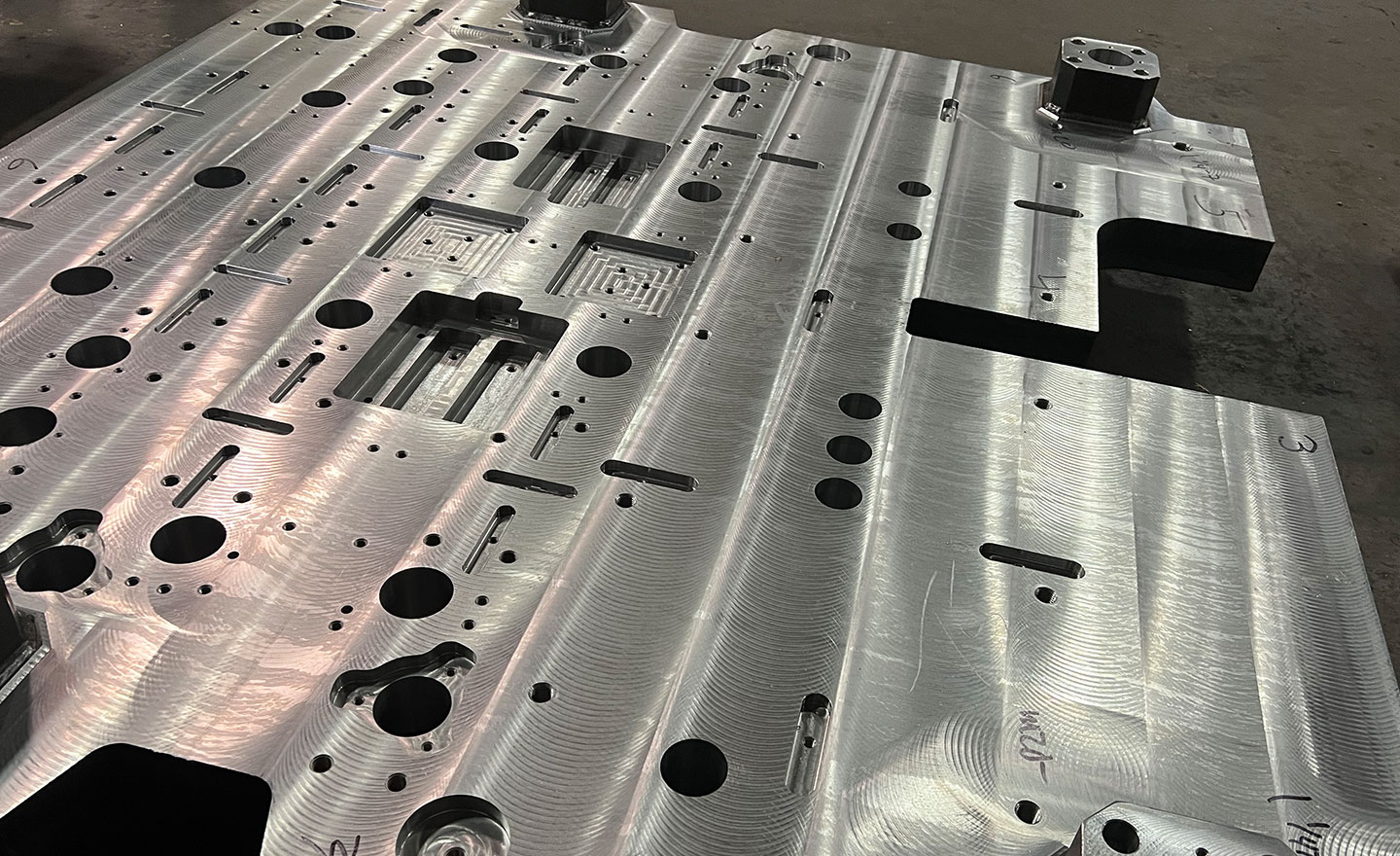

No surface is ever perfectly flat. Flatness is a form control tolerance that is measured relative to itself; all the measurements along the plane of the steel plate or surface must be within a specified tolerance level to be considered flat, or additional processes such as precision or Blanchard grinding would be required to bring the part into tolerance. Flatness is important for parts that must wear evenly, such as gears, or for parts that will be mounted flush to another part.

If a part is out of flatness tolerance:

- Uneven wear

- Mechanical breakdown or failure

- Faulty joins

- Shortened part lifespan

- Faulty finished products

- Issues with structural integrity

Parallelism

While flatness is measured relative to itself, parallelism is always measured relative to a datum or fixed base. Parallelism is directly related to how well a part or surface operates in relation to other parts or surfaces and can never be greater than the size tolerance.

There are two types of parallelism:

- Surface parallelism references two surfaces or features. When surfaces must work in sync such as when a part must slide between other parts without contact, surface parallelism ensures the two surfaces remain equidistant.

- Axis parallelism creates a cylindrical tolerance zone to ensure that the size of holes relative to the datum or cylindrical pins remain in tolerance. The tolerance for axis parallelism will always be in relation to the diameter of the cylinder.

For the most part, when parallelism is referenced, surface parallelism is intended, but if a central axis is referenced, it could refer to axis parallelism.

Why Flatness and Parallelism matter

Flatness is always measured relative to itself, while Parallelism will always reference a datum.

Steel is never perfectly flat. Depending on the relative thickness of the part being fabricated, it is possible to achieve parallelism with Blanchard Grinding, yet still have imperfect flatness. This can occur with plates that are relatively “thin” with regards to length and width.

The magnet holding the parts to the table of the Blanchard grinder will hold the parts securely until the magnet releases. Any residual stresses in the plate may spring back once it is released.

Flatness

Flatness is important in manufacturing for parts that require air-tight or liquid-tight connections and ensures even wear across all surfaces.

Changes in temperature can result in changes in flatness, so the control tolerance parameters are essential to ensure that the surfaces remain consistently flat.

Parts that will be bolted down to a frame, or used as a spacer between two thicker plates may function fine with less than perfect flatness, and it’s important to work with an experienced fabricator to avoid over-priced, over toleranced fabrication quotes.

Flatness is also an important aesthetic component for architectural features, both for the finished design appearance, and to ensure that panels fit together seamlessly.

Parallelism

For parts that must move in sync with other parts seamlessly, Parallelism is essential. Both the quality of the finished product and the efficiency of the manufacturing operation can be impeded if the moving parts are not in sync.