1. Size equals access

Anchor Danly is one of the the largest purchasers of steel plate in North America. In addition to keeping an inventory of 4000 tons of steel inventory on hand, our size allows us to purchase directly from domestic steel mills and have access to international sources. Not only can we negotiate better prices, we can guarantee 100% traceability to the mill.

2. Longevity

Anchor Danly was founded by Robert C. Danly and his son, Philo Danly as Danly Machines in Cicero, Il in 1922, and has been in business consistently since. Through strategic acquisitions and a commitment to excellence and quality, Anchor Danly has grown and evolved to meet the changing needs of its customers and the markets they serve. Our financial growth and stability make us the industry partner who will be there for the long-term.

3. Location, Location, Location

Anchor Danly operates multiple manufacturing facilities in the highest-density customer service regions along the Great Lakes and Ontario region, which equals almost three-quarters of North American tooling demand. We have a dedicated outside sales force located across North America to address any inquiries, concerns or customer needs no matter where our customers are located. We back up what we sell and are committed to building long-term relationships with our clients.

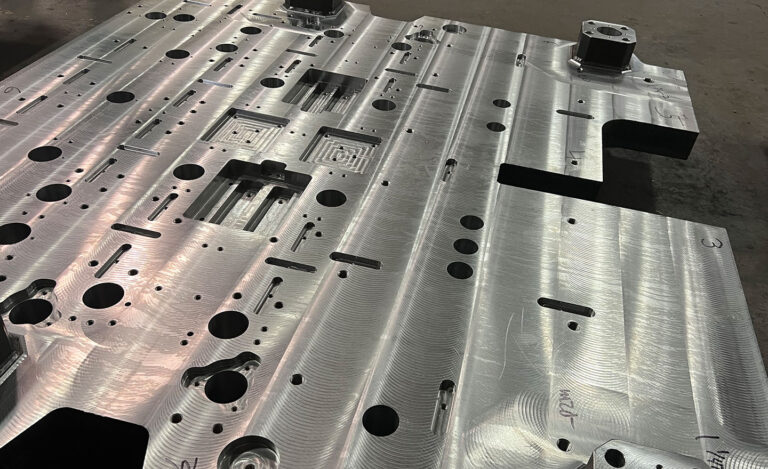

4. Capacity

We have a diverse strategic capacity for steel plate and metal fabrication. We offer:

- Scaled facilities (240,000+ sq. ft.)

- Blanchard Grinding to 144”

- Thickness Capability to 16”

- Torch Cutting to 150” x 280”

- Machining to 120” x 360”

- Delivery up to 35,000 lbs (15,800 kgs)

We can meet all customer needs from rough & ground plate to fully assembled die sets to fully machined fabrications, and we stand behind every product we sell.

5. Direct Access

Anchor Danly is the OEM for Danly, Lempco and Anchor die sets, and the official distributor for Danly IEM, Lamina, and Lempco die & mold components, Hyson and Kaller Gas Springs, and Lamina Hydraulics. When you purchase from Anchor Danly, you deal directly with the manufacturer and official distributor, not a representative.

6. Supply Chain Solutions

Anchor Danly has multiple North American locations, we buy directly from local steel mills, and we stock:

- Standard steels include hot rolled Type AISI A36, 44W, and 50W1020 mild steels

- Carbon steel plate in thickness between 0.25 inch and 15 inches

- Custom and standard steel plate sizes up to 120 inches x 360 inches

- Specialty steels including 1045 and 4140 (mild and pre-hardened) 1½ inch thru 6 inches thick (12.7 mm thru 152 mm)

- Variety of structural steel profiles, tubes and shapes

We are capable of processing steel plates with thickness ranging from 3/8 inch to 16 inches (9.5 mm to 400 mm). We provide end-to-end steel and metal manufacturing solutions, including grinding, blasting, finishing and painting, and we can deliver it up to 35,000 lbs. (Heavier loads available on request).

Our multiple North American locations in primary markets provide proximity to our customers, faster turnaround and logistics assistance.

7. Innovation

A company doesn’t stay in business for over 100 years by remaining stagnant. Did you know:

- Co-founder Robert C. Danly held patents for sand blast, magnetos, leader pins for die sets (1925), multiple feeding mechanism improvements. An inventor through and through, Robert also held patents for mechanisms for tuning tympani, snare drums, the drum beater mechanism, and the neck attachment for a banjo.

- Philo Danly held patents for a template for drawing die sets, brake assemblies, power press lubricating and safety systems, and a three-wheeled tractor assigned to International Harvester.

- Danly created and patented a hydraulic piercing machine for the De Havilland Engine Company that reduced processing time from 30 hours to 5 minutes.

- The various iterations of the Danly Manufacturing dynasty were the first to create (and patent) die sets with interchangeable parts, customer specific die sets made from thermally stress-relieved steel plate, quick die change sets, interchangeable bushings, mechanical presses, hydraulically operated piercing machine, forming machines, ball bearing die sets and several other constant innovations.

8. Expertise

Anchor Danly has been able to attract and retain employees who are professional, long term die, die set, steel plate and fabrication experts and highly skilled technical experts who can optimize ordering, assist with design and answer any questions customers may have. Some of our employees have been with us for decades.

Our direct sales staff know our products and the market and are available across North America to provide any kind of assistance.

Anchor Danly can provide end-to-end engineering services, including engineering support, project management, and fabrication design support, modularization support, and we will work with you to manage shipping and logistics.

Our Canadian fabrication locations are CWB certified for carbon steel and our U.S. location is AWS certified welders. Our facilities are ISO certified.

Since 1922, Anchor Danly has been committed to providing quality tool and die, metal and steel plate, fabrications, weldments and components to our customers.