Die Sets

Anchor Danly specializes in building die sets for tool and die makers. Die sets are manufactured in sizes up to 120 inches x 360 inches (3000 mm x 9000 mm).

Standard in-stock die sets are available in plain bearing and ball-bearing styles.

For over 40 years, die makers have been building their stamping dies with Anchor Danly die sets. Anchor Danly die sets are manufactured using state-of-the-art equipment. Each die set is manufactured to your specifications.

Anchor Danly manufactures Anchor, Danly, and Lempco brand die sets.

Our engineers can provide the design support you need. Whatever the size, we have the expertise and equipment to build the die set you require. Call us today and see why Anchor Danly is the preferred die set supplier to the tool and die industry.

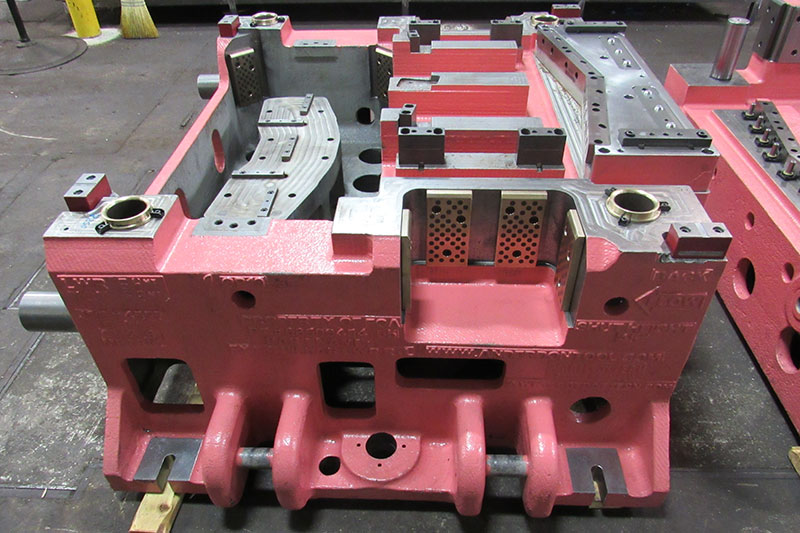

Custom Die Sets

Our technical competence, rooted in years of experience, and our state of the art Engineering & Design equipment and software, allow us to work with you to design and develop die sets to your specifications.

Turnaround time is based on our customers’ requirement and dependent on the size, complexity and type of die set.

Custom die set specifications differ with each order and typically include the size of the die set, the location of the pins, the thickness of the steel, the type of bushings and the special machining required. Our die set engineering department reviews each customer drawing prior to manufacture.

Anchor Danly builds a full range of custom die sets from the smallest to very large die sets measuring 120 inches x 360 inches (3000 mm x 9000 mm). Turn-around time for custom die set manufacture is approximately two to six weeks depending on size and complexity of the die set.

See the Ball Bearing Die Set or Plain Bearing Die Set catalogs for specifications.

Standard Die Sets

Standard die sets are available from inventory, and are manufactured to standard dimensions with respect to pin size, location and steel thickness. They are available in two post and four post models. Stock die sets have fully interchangeable components with each size.

Stock die sets are manufactured to standard dimensions with respect to pin size and location and the thickness of steel used. You can choose from two and four post models, in both plain and ball bearing styles. Anchor Danly’s standard line of die sets has fully interchangeable components with each size. Anchor, Danly, and Lempco brand standard die sets are stocked and ready to ship.

See the Danly Die Sets or Anchor Die Sets catalogs for specifications.

Die Set options include:

- Ball Bearing die sets

- Plain Bearing die sets

- Back Post die sets

- Center Post Die Sets

- Diagonal Post Die Sets

- Two Post Die Sets

- Four Post Die Sets

- Econoline Die Sets

Die sets are available from all Anchor Danly die set manufacturing locations in North America.

Cast Die Sets & Components

Anchor Danly manufactures cast iron and cast steel die sets for metal stamping. Dies are available is variety of iron and steel materials. Our cast die set manufacturing capabilities include pattern manufacturing, 2D and 3D machining, guide component installation, and design assistance. Pattern review for customer approval is available.

Cast Die Set Materials include:

- GM238 (G2500 Iron)

- GM241 (G3500 Iron)

- GM245 (D4512 Iron)

- GM246 (D5506 Iron)

- GM338 (D6510 Iron)

- S-7 Tool Steel

- D-2 Tool Steel

- A-2 Tool Steel

- GM190 (0050A Steel)

- GM68 (0030 Steel)

See the Cast Die Sets and Components Flyer for more information.

Aluminum Die Sets

Any die set offered by Anchor Danly in steel can also be manufactured from aluminum.

Aluminum die sets weigh approximately one-third as much as an identical size steel die set, thus reducing press wear. They are easier to handle, transport and store. When made with ball bearing components, these are available and are ideally suited for high speed, high precision applications. Aluminum die sets are often used when stamping precision components for the electronic and canning industries.

Aluminum die sets, in conjunction with ball bearing components, provide a lightweight, highly accurate guidance system. Ball bearing components under preload have superior guidance when compared with plain bearing components’ clearance fits.

See the Aluminum Die Sets Flyer for more details.