Blanchard Grinding Services

Anchor Danly has been Blanchard grinding steel plate for almost 40 years. Because of consistent high quality and experience, our Blanchard grinding and steel plate services supply a wide range of tool & die and OEM manufacturers.

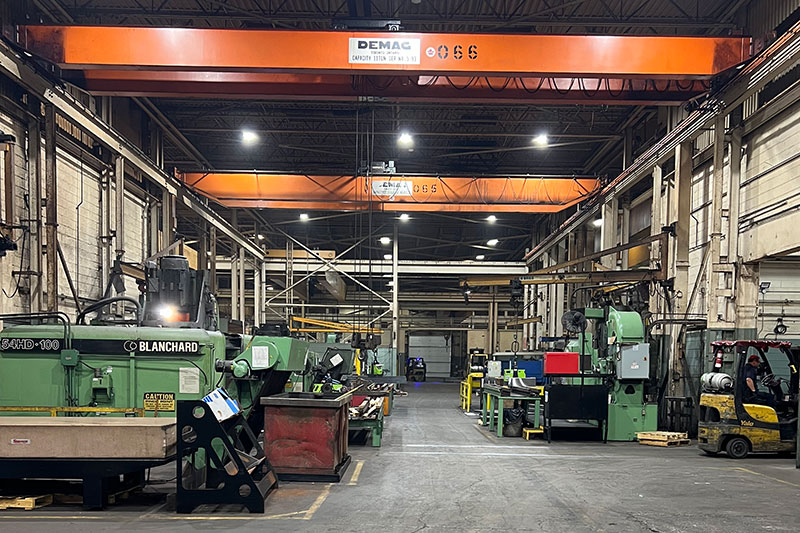

Today, Anchor Danly has one of the largest Blanchard grinding and steel plate service facilities in North America.

Blanchard Grinding Facilities

Anchor Danly’s modern facilities offer Blanchard grinding of steel plate as a core service. Thirty-four (34) Blanchard grinders are available. In addition to Blanchard grinding, we offer in-house CNC machining, thermal & vibratory stress relieving, metal fabrication, and finishing.

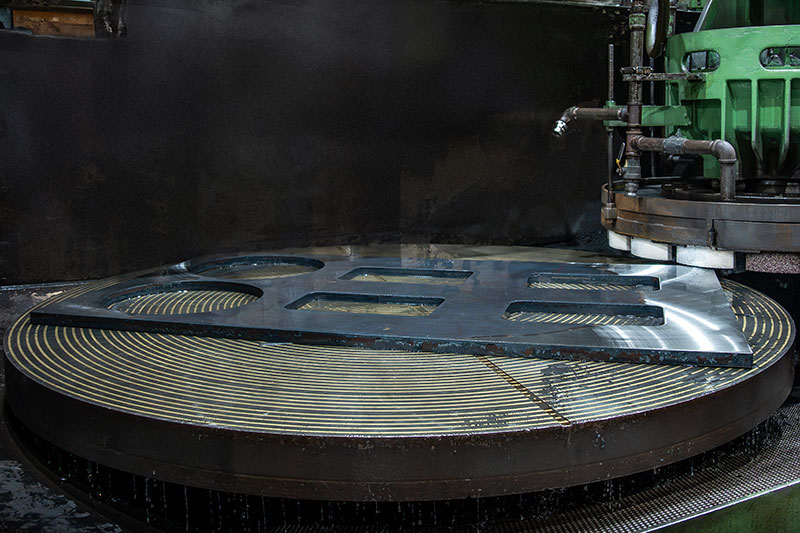

Our Blanchard grinders can accommodate single part weights up to 30,000 lbs and a part size envelop of 144 inches across the diagonal x 35 inches high. Our Blanchard grinding service is ideally suited for grinding large steel plate and steel plate fabrications.

Anchor Danly’s secondary processing and finishing capabilities for Blanchard ground steel plate includes CNC milling capacity of 138 inches x 320 inches and ovens to anneal or stress relieve steel plate.

Customer supplied material is accepted or choose from our extensive steel plate inventory.

Stress Relieving for Ground Steel Plate

Blanchard Grinding Capabilities

Blanchard Grinding Tolerances

Anchor Danly is able to achieve the following general tolerances for Blanchard ground steel plate:

- Dimensions to plus or minus 0.002 inch

- Parallelism to 0.0015 inch per foot (maximum of 0.006)

- Flatness to 0.0015 inch per foot (maximum of 0.006)

- Surface finish 125 rms

- Other tolerances and finishes available upon request

Blanchard Grinding Benefits

Blanchard Grinding at a Glance

- For large stock removal

- Surface finishes to 125 rms (3.1 microns)

- Grinding of annealed or hardened steel plate up to 62 Rc

- Multiple parts ground simultaneously

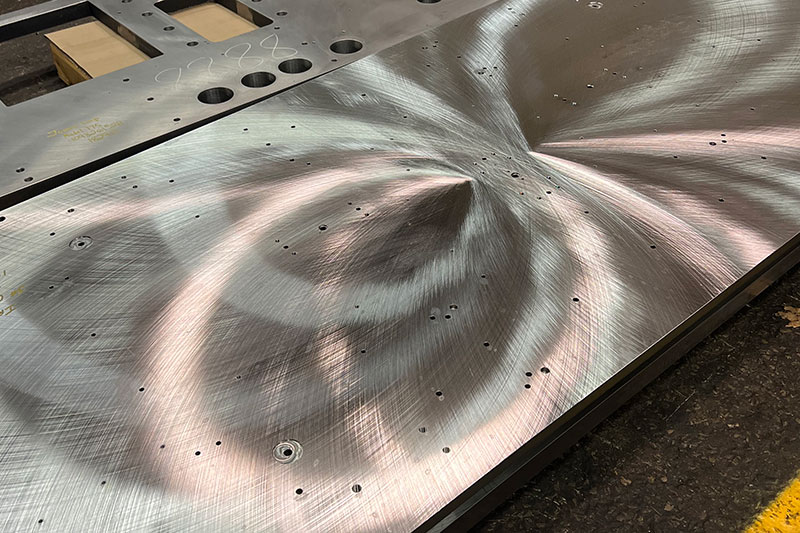

- Blanchard ground finish has a cross-hatched swirl type pattern

- Rotary surface grinding

- One side is ground at a time

- Ferrous materials are held on a magnetic chuck

- Vacuum chucks or special fixtures for grinding non-magnetic materials

- In-house thermal and vibratory stress relieving

- Secondary CNC machining

- Roughing for subsequent finishing operations